NFFA technology products

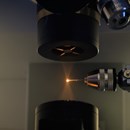

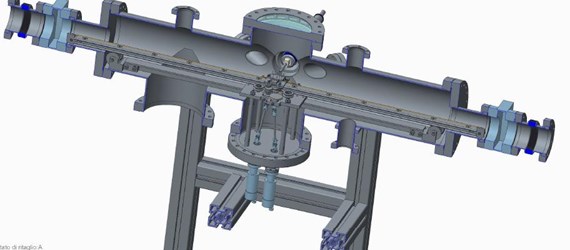

A compact transfer system has been designed and built by the IOM-CNR design engineer and mechanical workshop technician (see pictures) within the NFFA project. This system permitted the construction of the MBE-Cluster with a user friendly layout and no long transfer arms sticking out from the sample chambers. The transfer system which has the shape of a tube connect two different UHV chambers with a horizontal rail that can penetrate either one or the other of two opposite chambers and the sample can run on a belt driven cart from one end to the other where it can be picked/deposited with standard UHV forks. The mechanism (depicted in figure 1) is activated by two UHV rotary feedthroughs (on CF 16 flange) that move two belt that pull the rail and the cart respectively. In this way the sampleholder (the cart can carry up to 4 sampleholders at time) can be moved between two chamber by simply rotating the two feedthroughs. The total travel of the system is 2 meters, but can be easily modified for a longer travel thanks to 2 support wheels at the end of the rail that ensure the mechanical stability and prevent the bending of the rail. The systems are designed for minimum number of moving parts and ease of reach of UHV.

Figure :(left) Picture of internal mechanism of the transfer system, (right) 3D model of the mounted system.

Mechanical Technician :Aleksander De Luisa(left) , Federico Salvador (right)

Mechanical Technician :Aleksander De Luisa(left) , Federico Salvador (right)