SPECIFICATIONS

|

gas tip internal diameter

|

70 μm

|

|

pressure@ gas nozzle input

|

4-6 bar

|

|

main chamber base pressure

|

around 10-5 mbar

|

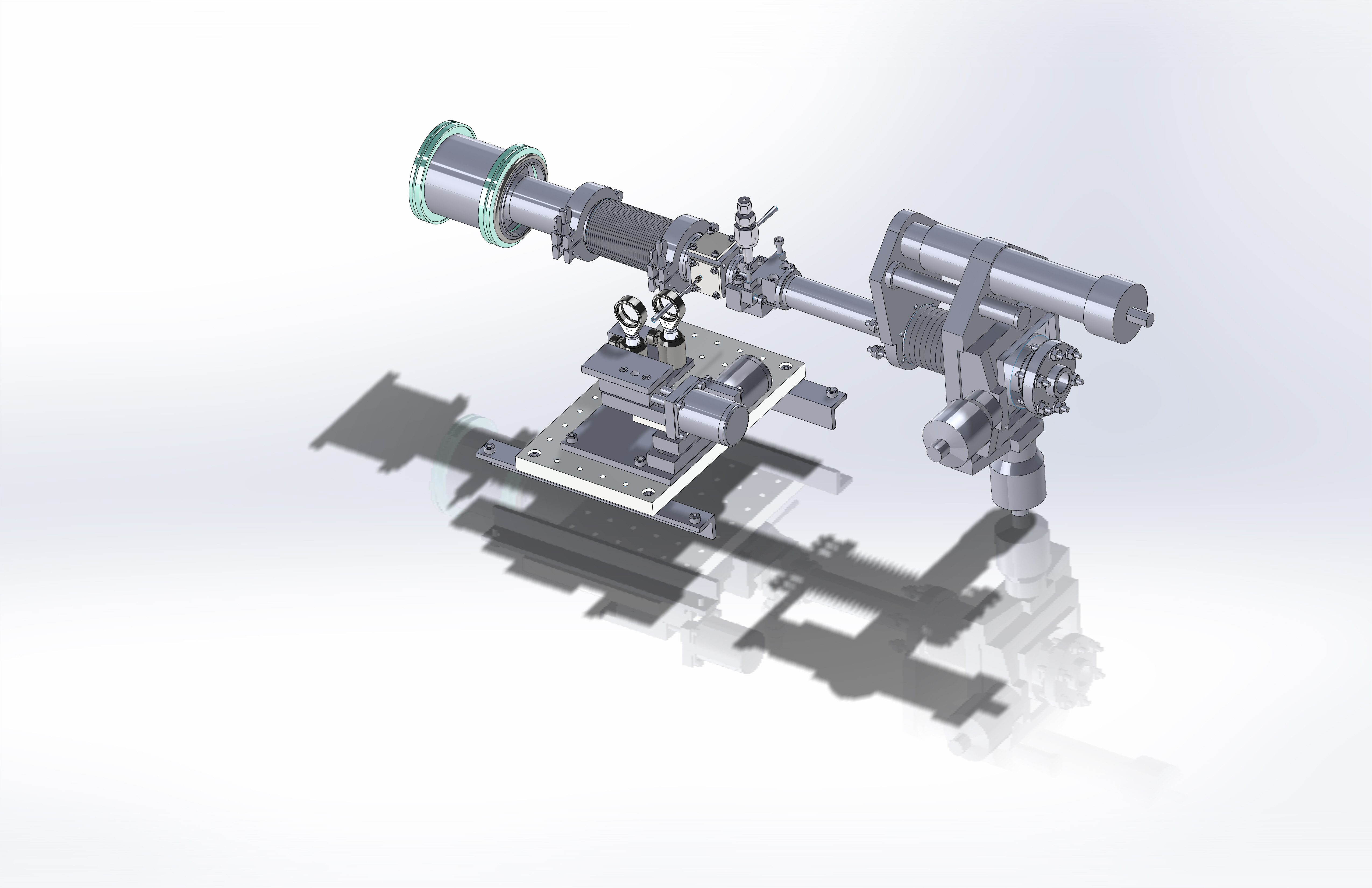

The HHG beamline @ SPRINT is characterized by three main chambers: generation, monochromatization and refocalization. The tight-focusing geometry chosen for generation requires the use of a gas nozzle inside the generation chambers to guarantees enough gas pressure for generation of high harmonics.

In order to maintain a good vacuum level without overloading the main turbomolecular pump, a second chamber is installed around the gas nozzle, consisting in a sharp glass tip having 70 μm internal diameter. This chamber is directly connected via an in-vacuum feedthrough to a 140 m3/h primary pump. The only apertures of the inner chamber toward the main chamber are two adjustable holes for the beam entrance and exit.

The two holes should be filled by two flow limiters, which reduce the entrance hall to dimensions close to the spot size, increasing the pressure inside the small chamber.

This solution allows to routinely apply a gas pressure of several (4–6) bars at the gas nozzle input while maintaining a base pressure of around 10−5 mbar in the main chamber. The gas nozzle is connected to a translation stage, which is used to optimize the nozzle position with respect to the laser beam.

The manipulator fixes the position of the nozzle into the ideal source point for optics downstream.

3D AND MECHANICAL DRAWINGS

3D model (pdf) - ![]() download and open with Adobe Acrobat

download and open with Adobe Acrobat

To have the 3D full project in various formats for free, contact info.ts@nffa.eu

CITE

NFFA High harmonic generation chamber

by CNR-IOM Headquarters

Source work URL: https://www.trieste.nffa.eu/open-source-lab/high-harmonic-generation-in-gas/.

LICENSE

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

The proper acknowledgement of the source must be guaranteed.

GALLERY